The best way to maintain your home’s beauty and hygiene.

All Maintanence You Need to Know

Safety Working Process

A workplace safety program consists of all the processes, protocols, and guidance put in place to help mitigate risks on-site and reduce injury and illness rates. All employees must be fully invested and committed to these workplace safety tips to help create a safer work environment. When the workforce shows a dedication to safety, different risks and hazards on-site can be quickly identified and corrective actions can be set.

Benefits of Safety in the Workplace:

When the workforce is truly dedicated and comes together to help create a safe working environment, this will contribute to less injuries and illnesses on-site, which will in turn offer myriad benefits.

Let’s take a closer look:

- Increase in efficiency and productivity with less Days Away, Restricted, or Transferred (DART) rates and Lost Time Injury (LTI) rates.

- Reduction in injury and illness costs and insurance claims with less workers injured on the job.

- Boost in employee morale and less employee turnover with more workers who recognize their safety and well-being is a company priority.

- A stronger, more resilient safety culture with everyone dedicated and invested in protecting team members and themselves.

- A better safety record with less injuries and illnesses on-site and more workers protected daily.

A safer work environment is a win-win situation for everyone involved. Work towards prioritizing education for team members on key safety tips they can use on an everyday basis.

8 Safety Tips in the Workplace

Certain work safety tips can be followed by all employees to help create a safer work environment. Though the following tips are not the only ones out there, they illustrate key fundamental ideals to contribute to less risk on-site:

1. Always Report Unsafe Conditions

At times, workers can feel hesitant to share specific unsafe conditions and hazards to their superiors, in the fear of getting themself or someone else in trouble. This is not conducive to a safe work environment as it may increase the potential for an accident or injury to occur on-site. All members of the workforce must report unsafe conditions immediately to help protect their co-workers and themselves. Once a hazard or risk is identified, follow the proper procedure to inform key players to help mitigate risks quickly and effectively. To learn more, read our blog on the 5 Steps to Identify and Assess Workplace Hazards.

2. Keep a clean workstation

Employees should avoid any unnecessary items near or on their workstations. They must also always remember to clean their workstations from any spillages and thoroughly sanitize the area if shared with other co-workers. According to EHS Daily Advisor’s article, OSHA’s Fatal Four – Leading Causes of Fatalities in the Workplace, 36.5% of all workplace deaths are attributed to falls. In fact, slips, trips, and falls result in multiple workplace injuries every year, so remind employees to take this OSHA compliance safety tip seriously.

3. Wear protective equipment

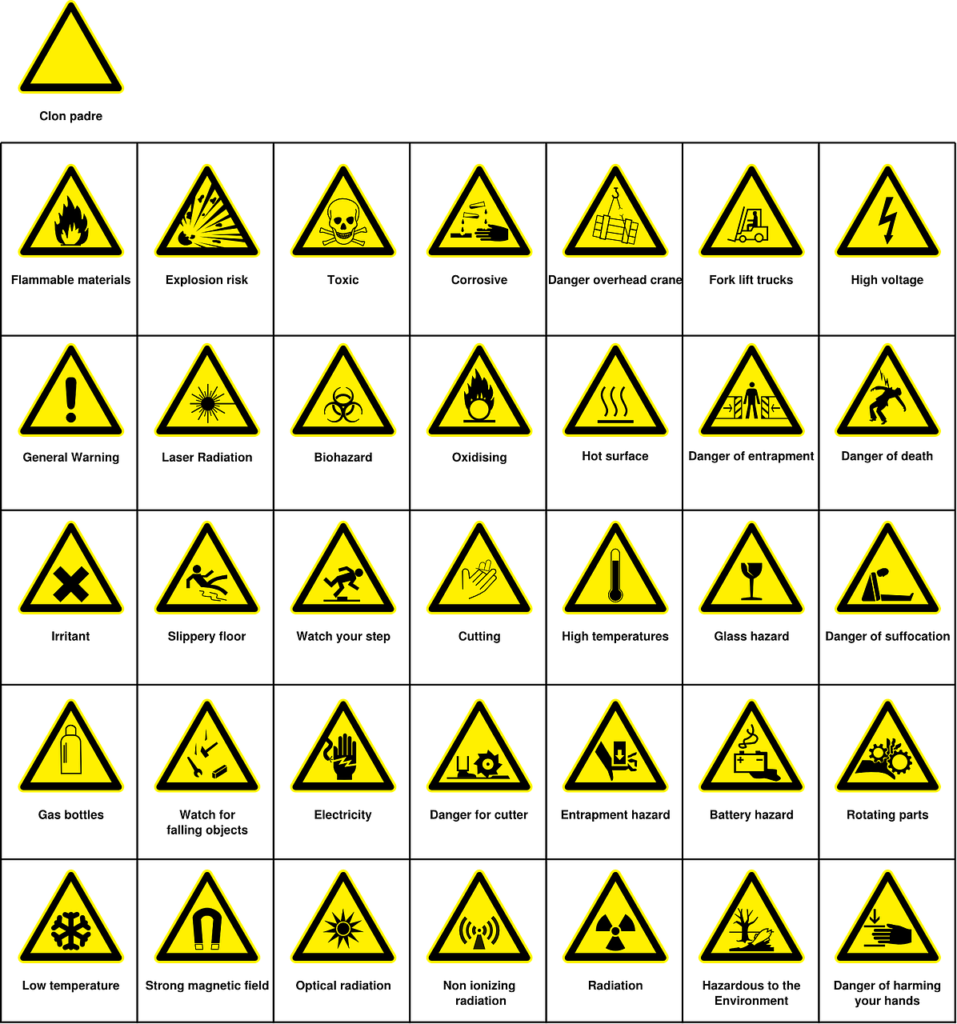

Though this tip may seem obvious, it’s important to remind workers to always wear the necessary personal protective equipment (PPE). Oftentimes, workers may forget or choose not to wear a specific piece of equipment such as protective goggles or a hard hat, as they feel it may be unnecessary or that they can finish the task quickly without it. Personal protective equipment is assigned to keep workers safe and protect them from injury or illness, so always remind them to wear the proper PPE assigned for the task.

4. Take breaks

Employees who are tired and overworked are a liability on the worksite. Taking breaks is important to help workers rest and recharge before completing certain tasks. Tired team members may pose a risk as they are not able to fully focus on the task at hand, which could cause an incident or accident, potentially harming themselves or others.

5. Don’t skip steps

At times, workers may be in a rush to complete a task so they might skip steps to finish faster. They may also not use certain equipment or tools in the proper way to quickly get the job done. This must be avoided at all costs. Remind team members that procedures and workflows are carefully put in place to avoid any chance of risk, so the safest option is to follow them.

6. Stay up to date with new procedures or protocols

New procedures, protocols, or even equipment can be introduced to the workplace, so ensure workers are always aware and up to date with these new elements. Proper training and education must be provided to help workers understand what needs to be done to avoid a potential incident. Foster a culture of support and encourage workers to ask questions and speak to their supervisor if they need more help.

7. Maintain proper posture

It’s important to carry out job tasks with proper posture. From lifting heavy objects to even sitting at a computer, this safety tip is easy to forget when you are caught up in a task. Employees must keep proper posture in mind because it can help them avoid aches, pains, and potential long-term harm to their neck, back, or shoulders.

8. Offer guidance to new employees

Seasoned and experienced team members should always offer guidance to newer employees. Educating them on the organization’s safety culture and the standards it upholds is essential to keep a strong foundation of safety. If all team members are fully invested in the value that safety offers to not only the organization, but themselves, they can work together to create a safe work environment and a stronger safety culture.

From reporting unsafe conditions to taking breaks, remind workers to always keep these work safety tips in mind to help ensure everyone gets home safely at the end of the day. It’s little steps like these that the workforce can carry out daily to help fortify the value of safety and the benefits it can offer.

By implementing a continuous improvement process, such as the Plan, Do, Check, Act Cycle, you can stay ahead of workplace injuries and your competition. Download the free whitepaper, Introducing Continuous Improvement as a Competitive Advantage to discover how a more proactive safety approach can benefit your organization.